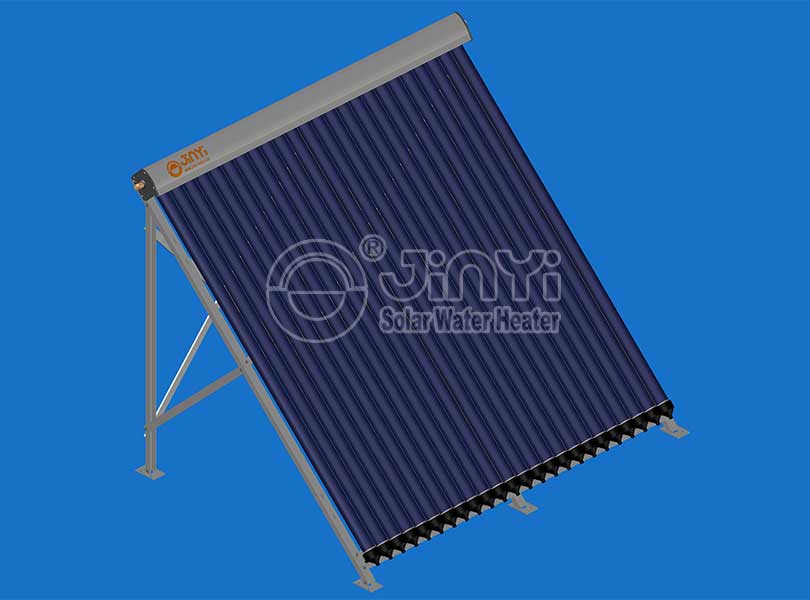

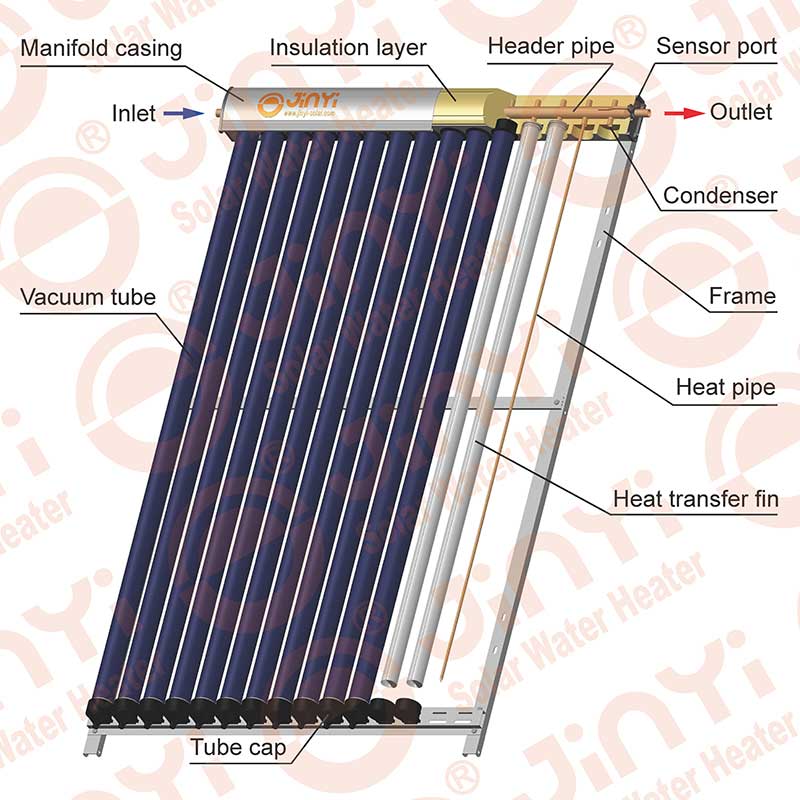

Heat Pipe Solar Collector(JHC)

Solar thermal collectors working principle:

The heat pipe solar thermal collectors always connected with existing water heating device. The selective absorber coating on the inner cover of vacuum tubes absorb solar energy, then convert solar energy into thermal energy and transfer thermal energy to heat pipe by aluminum fin. The heated liquid inside heat pipe change into vapor which rises to the top condenser, then thermal energy heat transfer liquid pass through heat exchanger and the cooled vapor becomes liquid, returning to the base of heat pipe.

The thermal energy conducts to transfer liquid via a copper pipe. This transference of heat into the liquid creates a continuous circulation as long as the collector is heated by the sun.

The characteristic of solar thermal collectors:

● Solar Keymark(EN12975) certified, click here.

● Higher efficiency η0 = 0.638 (aperture area).

● Heat pipe with 14mm diameter condenser, more exchanger area, rapid heat transferring, higher efficiency.

● Low temperature resistance, heat pipe freeze protected, even can be work under -50℃ ambient, so can be used all year round

in cold climate area.

in cold climate area.

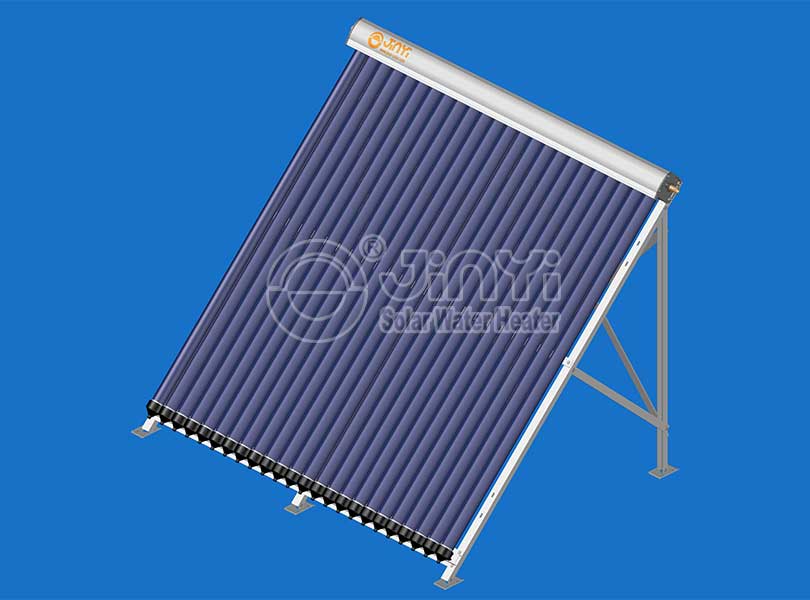

● Passive tracks the sun: the round absorber surface of vacuum tubes passively track the sun throughout the day.

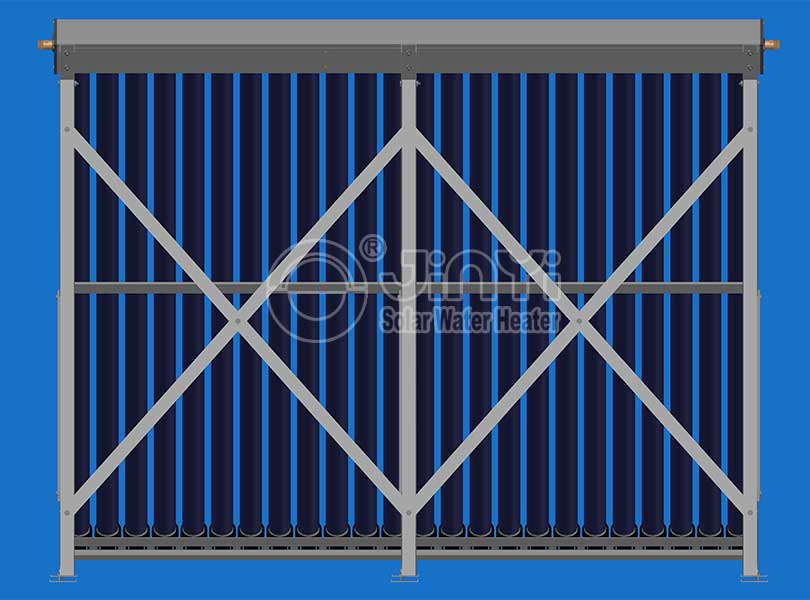

● Available in 10, 12, 15, 18, 20, 24 and 30 tubes model, flexible combination.

● No water inside vacuum tube, so vacuum tube will not break in the winter frozen weather.

● In the event of a tube damaged, the whole system will still keep working, just remove and replace, low cost.

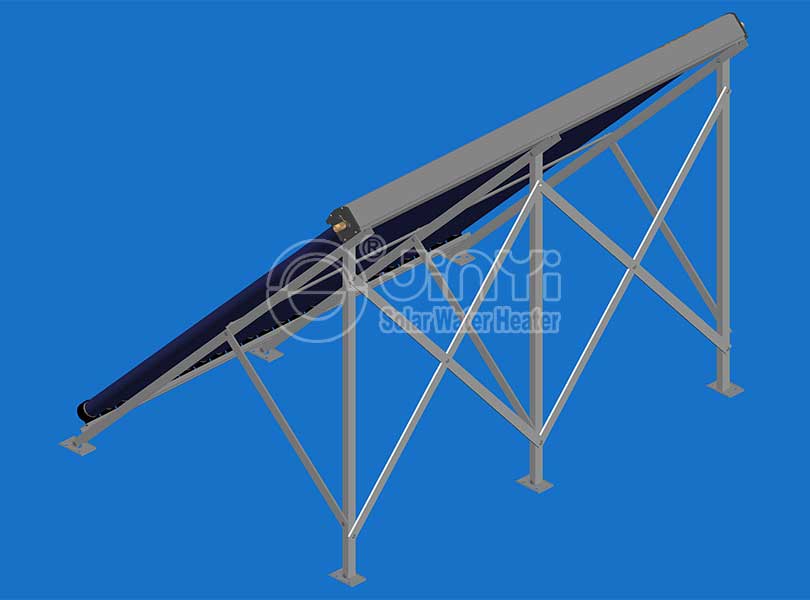

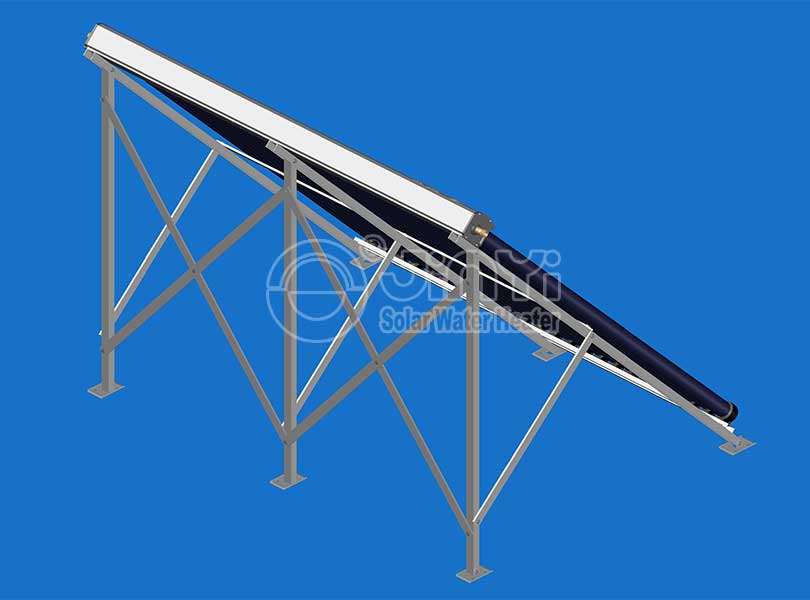

● Combined with building perfectly, ideal for slope roof or flat roof installation.

● It can be combined with existing water heating device easily.

● Tube can be replaced without draining solar fluid;

● Significant advantages over flat plate.

● Low maintenance!

|

|

| Solar Collector Key Components | Heat Pipe Vacuum Tube Working Principle |

Heat pipe solar collector specification:

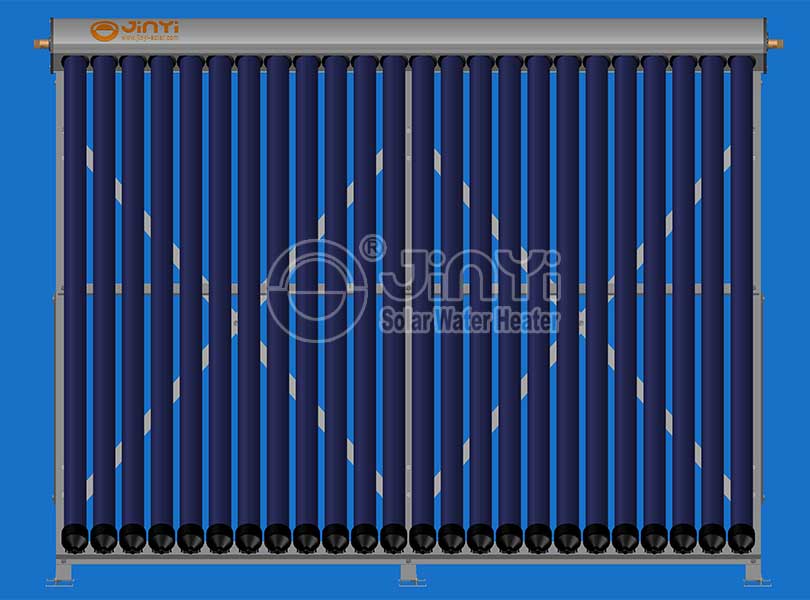

1. Vacuum tube: Borosilicate glass 3.3, ALN/AIN-SS/CU coating,Φ58×1800mm.

2. Heat pipe condenser: Φ14mm red copper.

3. Heat pipe: Φ8mm red copper.

4. Heat transfer fin: Integrated aluminium fin.

5. Manifold casing: Aluminium alloy(Color: silver and black).

6. Header pipe: Φ35mm red copper, .

7. Inlet/outlet: Φ22mm(3/4 and 1inch).

8. Insulation layer: Compressed rock wool.

9. Frame: Aluminium alloy.

10. Working pressure: 0.6MPa.

11. Max. working pressure: 1.2MPa.

12. Ambient temperature: ≥-50℃.

|

Tm-Ta | Global Irradiance G | ||

| G=400W/m2 | G=700W/m2 | G=1000W/m2 | ||

| 10k | 529W | 964W | 1392W | |

| 30k | 424W | 859W | 1292W | |

| 50k | 314W | 749W | 1173W | |

Heat pipe solar collector application:

1) Domestic water heating, such as shower, kitchen washing.etc

2) Room heating, such as under floor and radiator heating.

3) Old heating equipment/system retrofit.

4) Large scale commercial solar water heating system, such as hotel, apartment, school, hospital.etc

|

|

|||

| Reference area | Absorber area | Aperture area | Gross area | |

| η0 | 0.751 | 0.644 | 0.409 | |

| a1W/(m2k) | 2.57 | 2.2 | 1.4 | |

| a2 W/(m2k) | 0.0036 | 0.0031 | 0.002 | |

Parameter table:

| Model | Heat pipe vacuum tube | Condenser (mm) | Power output (W) | L/W/H (mm) | Loading Qty. (set) | ||||

| Dia. (mm) | Len. (mm) | Qty. (pcs) | 20GP | 40GP | 40HQ | ||||

| JHC-5818-10 | 58 | 1800 | 10 | Φ14 | 599 | 1960 x 890 x 138 | 164 | 338 | 394 |

| JHC-5818-12 | 58 | 1800 | 12 | Φ14 | 718 | 1960 x 1040 x 138 | 147 | 304 | 353 |

| JHC-5818-15 | 58 | 1800 | 15 | Φ14 | 898 | 1960 x 1235 x 138 | 131 | 270 | 314 |

| JHC-5818-18 | 58 | 1800 | 18 | Φ14 | 1078 | 1960 x 1490 x 138 | 106 | 218 | 254 |

| JHC-5818-20 | 58 | 1800 | 20 | Φ14 | 1198 | 1960 x 1640 x 138 | 100 | 205 | 238 |

| JHC-5818-24 | 58 | 1800 | 24 | Φ14 | 1435 | 1960 x 1940 x 138 | 88 | 180 | 210 |

| JHC-5818-30 | 58 | 1800 | 30 | Φ14 | 1797 | 1960 x 2390 x 138 | 74 | 152 | 177 |

Next: U Pipe Solar Collector