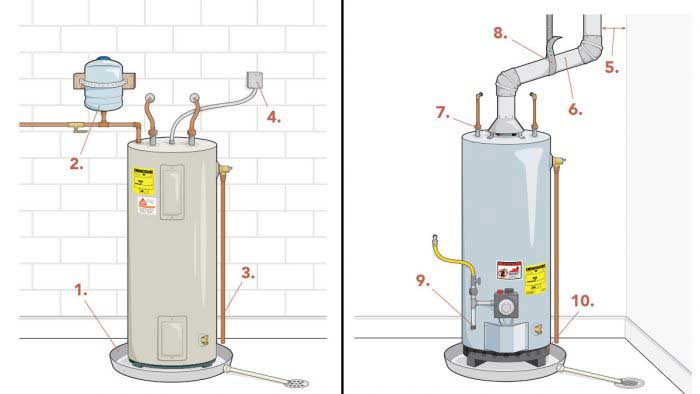

Top 10 Water-Heater Code Violations

Apr 18, 2020

Installing a tank water heater might seem easy, but some of these common mistakes could be life-threatening.

Synopsis: Installing a tank water heater might seem easy, but homeowners who refinish their basements often create a number of code violations with respect to the water heater. Code expert Glenn Mathewson describes 10 common water-heater code issues, including confusion about drip pans and drains, unsupported expansion tanks and plastic vents, lack of combustion air, and more. Some of these violations can be life-safety hazards, so avoiding these mistakes is crucial.

In the minds of many, installing a tank water heater is a piece of cake—an “I can’t believe I need a building permit to do this” kind of thing. These are the people who usually fail inspection. Indeed, a water heater can be easy to install, but replacing one in an existing home can introduce a host of complications. Some of this stems from the norms of the American home-building industry. Basements in new homes are usually left unfinished and pitched to buyers as a project they can easily tackle themselves when they need more living space. That day comes, and they go for it— frequently without a permit— unwittingly creating a number of code violations with respect to the water heater. One common mistake: boxing the water heater into a closet to hide it from view of the newly finished space. The deficiencies this creates surface when it comes time to replace the failing water heater and the building inspector shows up to sign off on the new installation. This kind of scenario happens more often than you might think; I see it all the time. There are a lot of code requirements around water heaters and not enough space to get into every one here. What follows are 10 of the most common code violations that I and other code professionals see out in the field when looking at water heaters, particularly replacement water heaters.

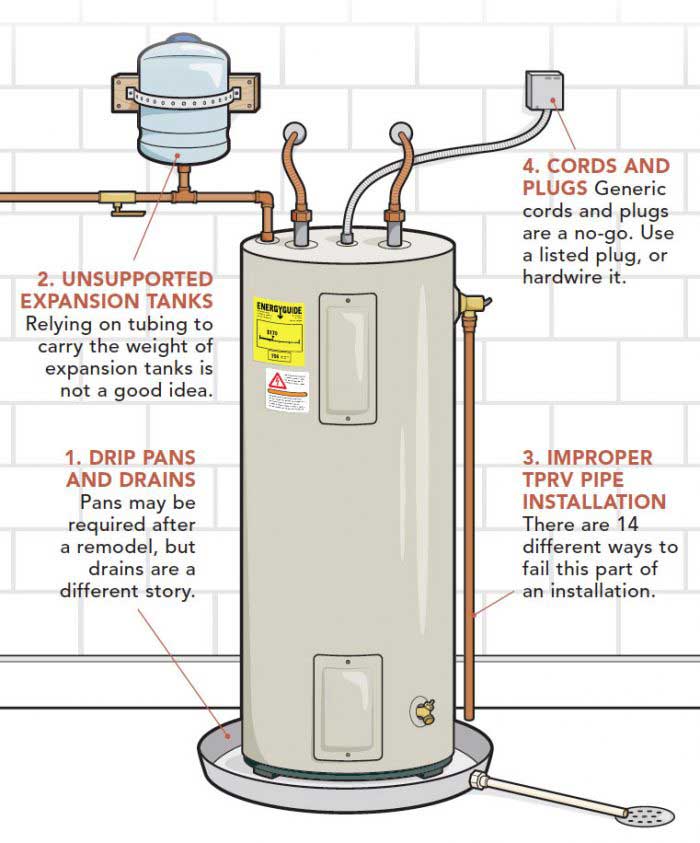

1. Confusion about pans and drains

Drip pans are required when tank-type water heaters are installed in places where a leak could cause damage. These pans are not meant to protect from a catastrophic tank failure; they’re meant to catch the slow leak that no one notices. In a basement with a concrete floor, damage isn’t generally a concern. When the basement is finished, it may be. Drip pans in new homes also require drains. Neither pans nor pan drains have always been required, and they have been a tricky issue when it comes to replacement water heaters in newly finished spaces. Is there a place to drain to, and a route to get there? Installers and inspectors long bickered over whether either was required in replacement installations where a pan and drain wasn’t previously provided. The 2015 IRC brought some clarity, stating that drains aren’t required when they weren’t previously provided. The pans themselves, however, must be installed if the water heater is located where a leak can cause damage. Prior to this, the top violation would have been not installing pans and drains with replacement water heaters—now, the issue is inspectors continuing to require drains without notice of this code change.

2. Unsupported expansion tanks

Some may tell you that an expansion tank is required at every water heater, but that isn’t in the IRC. Where requirements for expansion tanks show up in local codes, they’ve been added in. What is required is “a means for controlling increased pressure caused by thermal expansion … where required,” and that’s only necessary under certain conditions. Figuring out whether a particular installation meets those conditions can be complicated. The easy solution is to just add an expansion tank—it doesn’t hurt. But because it’s an easy way out, the default position in many locales has become “expansion tanks are required.” The real answer about whether they’re necessary should come from a professional installer, not a regulatory authority. There are other devices and methods for controlling pressure other than expansion tanks. When expansion tanks are included, physical support for them is something of concern, as installers often leave them simply hanging by the pipes they connect to. Read the manufacturer’s installation instructions before you do that. It’s not a good choice, and some local codes prohibit it.

3. Improper TPRV pipe installation

The temperature pressure relief valve (TPRV) is an incredibly important life-safety device on every water heater. Its proper functioning is the difference between a nice hot shower and an explosion. Unlike the expansion tank, which is intended to protect the piping system from pressure, the TPRV protects the water-heater tank from experiencing more pressure than it can handle. Here’s how your water heater becomes a pressure bomb: The boiling point of water that we are familiar with—212°F—is the temperature at which water at sea-level atmospheric pressure turns to vapor and greatly expands. But as pressure increases, so does the boiling point. This means that when pressure builds up inside a water heater, liquid water can get hotter than its atmospheric boiling point, until the tank ruptures. When 40 or more gallons of superheated water is suddenly brought to atmospheric pressure and instantaneously vaporizes, the massive expansion can launch your water heater through your house. The TPRVs themselves are not usually a problem on water-heater installations, as they come installed in the water heater. The problems occur in the pipe between the valve and the discharge point. The IRC provides a list of 14 specific criteria meant to keep this pipe open. It cannot connect directly to a drain system; must discharge through an air gap in the same room; cannot be smaller than the diameter of the valve it’s connected to; can only serve a single appliance; must discharge to the floor, pan, receptor, or outdoors; must not cause structural damage; must be observable to the occupants; cannot be trapped; must flow by gravity; must terminate within 6 in. of the floor or receptor; cannot be threaded or have any valves or tee fittings; must be made of materials approved for potable water; and must be one size larger and secured at the end when made of plastic tubing materials. Many installations are tripped up by a number of these specific requirements.

4. Unlisted cord and plug

Most items in this list apply to conventional gas water heaters, but electric water heaters are also common. The hazards of gas, venting, and combustion air are eliminated with electric appliances, but there is still one common violation to be found. These appliances are generally intended to be hardwired to a switch location, but installers often buy a generic cord-and-plug assembly and plug them into an available outlet. Electric water heaters can only be installed with a cord and plug where listed by the manufacturer for such installation, and they must use a cord and plug that has been listed for use with the specific make and model of water heater. This rarely happens, which is why I recommend hardwired installations.

5. Not enough vent and vent-connector clearance

Conventional tank water heaters generally utilize two types of vent and vent connectors: B-vent and single-wall. These vents get hot by design—a hot vent is part of what produces the draft required to remove the combustion products from the building. But B-vent and single-wall are not the same. B-vent has a pipe inside a pipe with an air space between them that insulates the outer pipe from the hot inner pipe. Because the outer wall of B-vent doesn’t get all that hot, code requires only 1 in. of clearance between it and combustibles. Single-wall vents get very hot, requiring a 6-in. clearance to combustibles. In an attempt to maximize finished floor space when boxing off the water heater from the rest of the room, people often don’t leave enough clearance between the new wall framing and the vent pipes. Basement-finishing projects are notorious for this code violation.

6. Insufficient vent and vent-connector slope

The ideal vent or chimney system is entirely vertical, though this is rarely feasible. More often, fuel-fired water heaters connect to a chimney or vent by way of a vent connector, which is essentially just another piece of pipe. The connector should be as short as possible and must slope upward from the water heater at a slope no lower than 1/4-in-12. Once it connects to the vent—the portion that leaves the building—things get more complicated. The general expectation is that the vent run vertically, with offsets no greater than 45° from vertical, but that is not the whole story. Vent-slope limitations hinge on a number of variables, including the diameter of the vent, length of the vent, type of vent, and a host of other things. Once a house is built and the vent system designed, it’s no easy task to evaluate and modify it later. When finishing basements, owners often find the water heater isn’t where they’d like it, so they move it and connect it back to the original vent with a long, low-slope vent connector. Long horizontal vent runs can greatly reduce the drafting ability of natural-draft appliances, and could lead to backdrafting of combustion gases into the home, creating a major life-safety hazard.

7. Incorrect draft-hood connection

Water heaters are tested and provided with their specific draft hood (draft diverter), but it doesn’t come attached; it’s in the box separately. The installer must attach the hood that came with the new appliance, and this almost always requires fasteners. Too often I’ve arrived at inspections where the hood from the old water heater is used on the new one. Even more often, the new hood is used but not properly fastened—the provided screws are still in a bag with the instructions, glued to the side of the water heater. This is a very embarrassing reason to fail inspection, so never forget the screws.

8. No support for plastic vents

High-efficiency power-vented water heaters with plastic, sealed vents are popular, especially in new, tight homes, and as replacements for conked-out conventional water heaters. They eliminate the issues with conventional vent clearances and slope, and can also relieve the issues of interior combustion air. The plastic vents can be installed horizontally, but they must be supported according to the manufacturer’s specs. Water vapor produced during combustion will condense inside these vents, so they must be sloped to drain. These horizontal vent pipes are often fished over finished ceilings in a basement and left unsupported. A sag in the vent can allow water to accumulate and affect the safe and efficient operation of the appliance. Though not a joy to anyone, sometimes a finished ceiling needs to be cut to install proper support for the vent.

9. Sediment traps that don’t work

A sediment trap and a drip leg are often considered one in the same, but not by the code. A drip is only required when wet gas (gas with a small amount of liquid present) exists. A drip simply needs to allow gravity to collect the liquid in the low spots. A sediment trap is required when an integral trap is not provided in the appliance, and it usually isn’t. From manufacturing to service, gas pipe goes through quite a bit of handling, cutting, and threading that can leave some debris— usually bits of metal—in the pipe. This debris, or sediment, can be small enough to get caught in the flow of the gas. Unlike a drip leg, gravity alone will not separate the sediment from the gas stream. A sediment trap requires a hard turn that the gas can flow around but sediment can’t—much like a sharp turn in a fast-moving go-kart has the potential to fling you out of the driver’s seat. Installing this correctly has been so misunderstood in the industry that the 2012 edition of the International Fuel Gas Code added a figure to show how it must be done.

10. Lack of combustion air

This is a big subject, with more to say than what follows. Combustion air does a few things: It ventilates the appliance, it provides oxygen for the fire, it feeds an open draft hood to maintain draft, and it replaces the air leaving the building with fresh outside air in order to maintain neutral pressure. In older homes, before the codes were loaded down with provisions for energy conservation, homes were leaky and interior-air calculations were done (or not done) to provide sufficient combustion air. A naturally leaky home will naturally allow replacement air (combustion air) to enter—this is one method allowed in the code. When the home was built, water heater installed, and combustion air designed, the water heater was likely in a wide-open unfinished basement. This offered a large volume of interior combustion air. With the air-sealing of homes and the finishing of basements— which often includes enclosing mechanical equipment in some sort of closet—interior combustion air gets choked off, and naturally drafting appliances get starved of air.

The above list is not a comprehensive discussion of all the code requirements for water heaters. But it does cover some of the most common mistakes— all of which are easily avoided if you know what to look for.

EDITOR’S NOTE: One of our readers who lives in a region with regular seismic activity reminded us that strapping or other bracing is required for buildings that fit into one of the Seismic Design Categories specified in the IRC. If you live or work in one of these regions, chances are that your local codes have more specific details about requirements and best practices regarding water-heater bracing, so please check with your local building department.