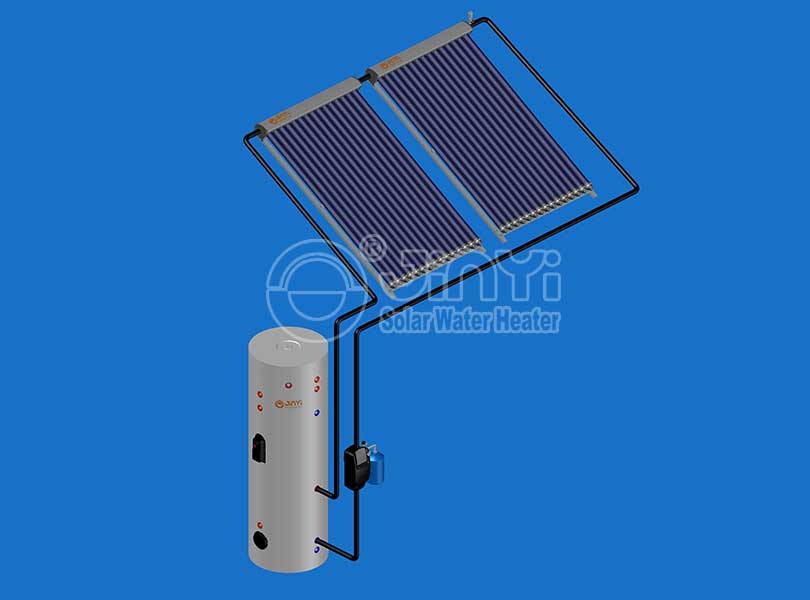

Heat Pipe Solar Heating System

Heat pipe solar water heating system working principle

Jinyi heat pipe solar water heating system is an active system, mainly including heat pipe solar collector, pressure water tank and pump station. Use a pump to circulate the fluid between heat pipe solar collector and water tank. Tank and solar collector are separated, solar collector could be installed on the roof or somewhere sunshine could shine on, while tank and pump station could be installed anywhere of the building. The piping between the tank and solar collector is twin way pre-insulated solar hose.

There are two types of active solar water heating system:

1) Direct system:

Tank without coil(heat exchanger), pump circulate household water through the solar collectors and into the home. This type works well in climates where it rarely freezing.

2) Indirect system:

Tank always have coil(heat exchanger), pump circulate anti-freezing heat transfer fluid through the collectors and tank via a heat exchanger. Tank water heated by the heat exchanger. Suit for climate where there have a risk of freezing.

Heat pipe solar water heating system characteristic:

1. No disorder water tank on roof

2. Pressure hot water, comfort bathing/washing

3. Collector module designed for freely assemble

4. Completely automatic operation.

5. Can be combined with traditional auxiliary energy resource

6. Suit for climate where there have a risk of freezing.

7. Solar collector not affected by scaling in hard water area.

8. Whole system Solar Keymark(EN12976) certified, please click here.

9. Heat pipe solar collector higher efficiency η0 = 0.769 (aperture area).

10. Available in 100L-1000L system, flexible combination;

11. 100L, 150L, 200L, 300L tanks with Europe Union Energy Efficiency Class A.

250L, 400L, 500L tanks with Europe Union Energy Efficiency Class B.

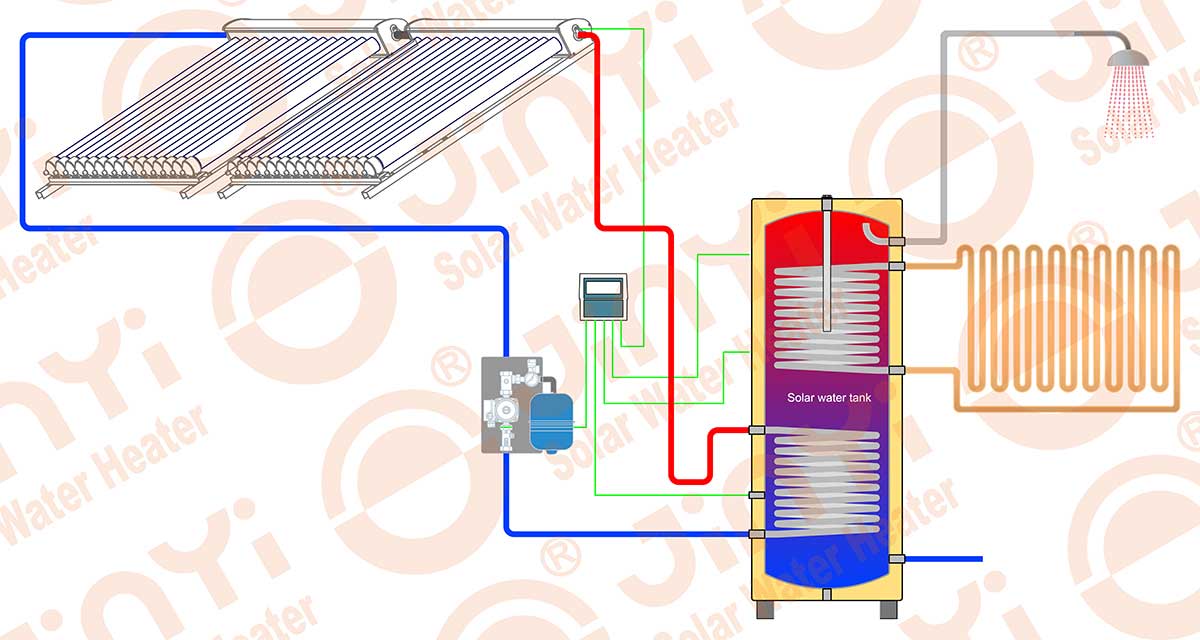

Heat pipe solar heating system schematic diagram

The main components:

2) Pressure water tank from 100L to 1000L.

4) Other necessary accessories: Expansion vessel, Check valve, T & P valve, Air vent valve, Pipeline, Connector, etc.

Solar water heating system schematic diagram (2 coil)

Parameter table:

| Model | Heat pipe solar collector | Capacity(L) | Person No. | Loading Qty. (set) | |||

| Tube No. | Collector No. | 20GP | 40GP | 40HQ | |||

| JSH2-150-18 | 18 | 1 | 150 | 3 | 38 | 76 | 88 |

| JSH2-200-24 | 24 | 1 | 200 | 4 | 28 | 58 | 74 |

| JSH2-300-36 | 36 | 2 | 300 | 6 | 21 | 42 | 50 |

| JSH2-400-48 | 48 | 2 | 400 | 8 | 18 | 36 | 42 |

| JSH2-500-60 | 60 | 2 | 500 | 10 | 15 | 29 | 33 |

Note:

1) Also have other tank capacity for chosen, such as: 600L, 700L, 800L, 1000L.

Accessories:

|

Temperature & Pressure relief valve

- Used for tank pressure release - Working temperature: 90℃ - Working pressure: 6 Bar |

|

Check valve

- Used for control one-way flow and prevent water from flowing back. - Material: brass. |

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 007 067 | 3/4 inch | 1 unit | 812 007 002 | 3/4 inch | 1 unit | |

|

Magnesium rod

- Used for tank protection

- Φ28 x 600mm length

|

|

Electric heater

- Material: Incoloy 800

- Super anti-corrosion& heat conduction, dry-heat resistant

- Connection size: 1 inch

|

|||

| Item No. | Size | Quantity | Item No. | Power | Quantity | |

| 812 801 002 | 1 inch | 1 unit | 812 900 191 | 1500W, 2500W | 1 unit | |

|

Automatic air vent valve

-With 1 unit shut-off Ball Valve

-Material: Brass

-Max. working temperature: 180 ℃

-Max. working pressure: 10 Bar

-Max. percentage of glycol: 50%

|

|

Reducing tee

-Material: Brass

-Connection size: 3/4 x 1/ 2x 3/4 inch

|

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 007 032 | 1/2 inch | 1 unit | 812 010 018 | 3/4x1/2x3/4 inch | 1 unit | |

|

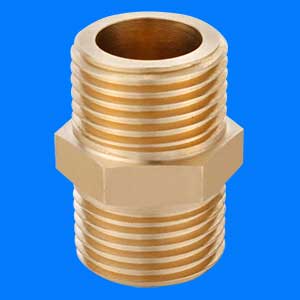

Equal male straight

-Material: Brass

-Connection size: 3/4x3/4 inch

|

|

Connection pipe

- Used for flat collector connection

- Component: Stainless steel corrugated pipe, brass nut

- Connection size: 3/4 inch

|

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 010 010 | 3/4 inch | 11 units | 812 010 038 | 3/4 inch | 1 unit | |

|

Pump station

- Collector temp. range: -10~200 ℃

- Tank temp. range: 0~110 ℃

- Max. working pressure: 6 Bar

- Input: 1 Pt1000, 2 NTC10K

- Output: 1 pump, 1 electrical heater

|

|

Expansion vessel

- Capacity: 18/24/60 L

- Max. working pressure: 10 Bar

- Working temperature: -10~90℃

- Pre-charge: 2 Bar

- Connection size: 3/4 inch

|

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 003 881 | 3/4 inch | 1 unit | 812 003 012 | 3/4 inch | 1 unit | |

|

Wall mounting kits

- Used for fix expansion vessel

- Pipe: Corrugated stainless steel

|

|

Thermostatic mixing valve

- Material: Nickle plated brass

- Cold water temperature: 5-29℃

- Hot water temperature: 50-95℃

- Regulating temperature: 35-55℃

- Working pressure: 0.03-1 Mpa

|

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 000 029 | 3/4 inch | 1 unit | 812 007 052 | 3/4 inch | 1 unit | |

|

Twin way pre-insulated solar hose

- Pipe: Corrugated stainless steel

- Jacket: UV resistant

- Insulation: EPDM,13 / 20mm

- Temperature sensor: 1 way cable

- Lenth: 15 / 20m

|

|

Ball valve

-Material: Brass

-Connection size: 3/4x3/4 inch

|

|||

| Item No. | Size | Quantity | Item No. | Size | Quantity | |

| 812 002 804 | 3/4 inch | 1 unit | 812 007 008 | 3/4 inch | 5 units | |

Last: no